When we think about the things that make our modern world function, it's easy to overlook the foundational elements. Yet, it's often the specialized components, the very building blocks of complex systems, that truly drive progress. This is where a name like isoprofil gmbh & co kg comes into the picture, representing a significant piece of the industrial puzzle. Very often, these kinds of companies play a quiet yet absolutely essential role in various sectors, making sure that everything from the structures we inhabit to the machines that produce our goods stands strong and performs reliably. It's truly interesting to consider how much depends on these foundational elements.

The name itself, "isoprofil," gives us a pretty good hint about what such a company might focus on: profiles. Think about the beams in a building, the frames of a machine, or even the intricate components inside a piece of consumer electronics. These aren't just random shapes; they are precisely engineered elements, designed to meet very specific needs for strength, weight, conductivity, or even aesthetics. So, in a way, understanding a company like isoprofil gmbh & co kg means getting a grasp on the backbone of many industries, which is that pretty much everything needs a strong framework.

This article aims to shed some light on the world of industrial profiles and the crucial part companies like isoprofil gmbh & co kg play in it. We'll explore why these components are so vital, how they are made, and what makes a specialized provider stand out. You know, it's almost like understanding the hidden gears that keep the big machines running smoothly, and we'll try to explain how it all fits together.

Table of Contents

- What is isoprofil gmbh & co kg?

- The Foundational Role of Industrial Profiles

- Precision and Tailored Solutions in Manufacturing

- Innovation and Future Directions in Profile Production

- Choosing the Right Partner for Your Profile Needs

- Frequently Asked Questions About Industrial Profiles

- Conclusion

What is isoprofil gmbh & co kg?

When we encounter a name like isoprofil gmbh & co kg, it typically points to a German-based entity specializing in the production and supply of profiles. The "GmbH & Co. KG" part, you know, is a common legal structure in Germany, essentially a limited partnership with a limited liability company as its general partner. This structure often signals a well-established, professional organization. In a way, it's a mark of a certain kind of business presence.

A company bearing the "isoprofil" name would, in all likelihood, be involved in creating shaped materials, often for industrial use. These profiles can come in a huge variety of materials, including aluminum, steel, various plastics, or even composite materials. Each material has its own set of characteristics, making it suitable for different applications. So, for instance, aluminum might be chosen for its light weight and corrosion resistance, while steel offers exceptional strength. It's really about matching the right material to the job, which is that a lot of thought goes into it.

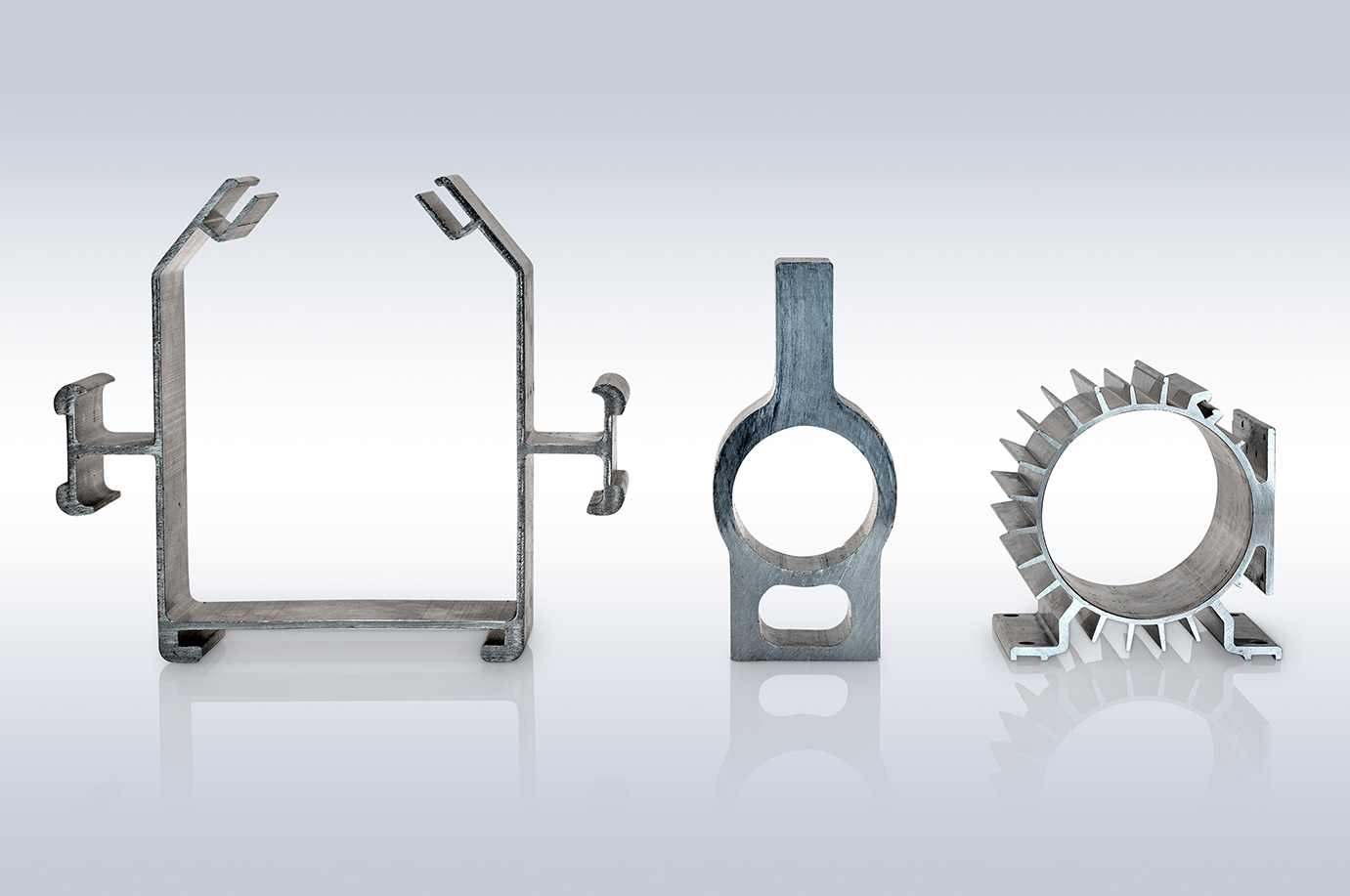

The core business of such an entity would revolve around designing, manufacturing, and distributing these profiles. This isn't just about making simple bars or tubes; it often involves complex cross-sections and precise dimensions. These profiles are then used as essential components in countless products and structures across a broad spectrum of industries. Basically, they're the pieces that fit together to build bigger things, and you'd be surprised how many different forms they can take. It's a bit like building with very specialized LEGOs, you might say.

Consider, for a moment, the sheer diversity of applications. Profiles are everywhere, from the framing of windows and doors in buildings to the structural elements within vehicles, the casings for electronic devices, or even the tracks for automated systems in factories. A company like isoprofil gmbh & co kg, therefore, serves as a fundamental supplier, enabling other manufacturers to build their products efficiently and reliably. It's a foundational piece of the manufacturing ecosystem, really, and it helps keep the gears turning. You could argue that without these specialized parts, a lot of what we use daily just wouldn't be possible.

The Foundational Role of Industrial Profiles

Industrial profiles are, quite simply, the unsung heroes of modern engineering and construction. They provide the necessary framework, support, and enclosure for an incredible array of products and systems. Without these specialized shapes, many of the items we rely on daily would either be impossible to create or would be far less efficient and durable. So, it's a very big deal, really, how much they contribute.

Think about the way things are put together. Whether it's a sophisticated machine that needs precise internal channeling for wires and fluids, or a large architectural structure that requires strong yet lightweight support, profiles are the answer. They are designed to optimize material use, reduce assembly time, and enhance the overall performance of the final product. This means they are not just pieces of metal or plastic; they are engineered solutions, each with a specific purpose. It’s almost like they have their own little job to do within the larger system, and they do it very well.

One of the key advantages of using profiles is their ability to be customized. Unlike standard, off-the-shelf components, profiles can be extruded, rolled, or formed into almost any cross-sectional shape imaginable. This allows designers and engineers to create highly specific solutions that perfectly fit their project's requirements, leading to improved functionality and reduced waste. This adaptability is, in a way, what makes them so incredibly valuable. It’s that ability to tailor them exactly to what’s needed, you see.

Furthermore, the choice of material for a profile is just as important as its shape. For example, in the medical field, as seen with specialized endoscopes, the components need to be incredibly precise, often made from materials that are biocompatible and easy to sterilize. Similarly, in the automotive industry, profiles might need to be lightweight for fuel efficiency but strong enough to withstand impact. A company like isoprofil gmbh & co kg would likely work with a broad range of materials to meet these diverse demands. It's a bit like picking the right tool for a very particular job, and they have a whole toolbox full of options, more or less.

The consistent quality of these profiles is also paramount. In applications where safety and performance are critical, any deviation in material properties or dimensions can have serious consequences. This is why reputable profile manufacturers adhere to strict quality control standards, ensuring that every piece meets the required specifications. It’s not just about making something; it’s about making it right, every single time, which is that a lot of trust goes into it. This commitment to quality, you know, really underpins the reliability of countless products worldwide.

Precision and Tailored Solutions in Manufacturing

The manufacturing of industrial profiles is a process that demands incredible precision and often, a high degree of customization. It’s not simply about cutting a piece of material; it involves sophisticated techniques to achieve the exact shape, size, and finish required for specific applications. A company like isoprofil gmbh & co kg would be at the forefront of these specialized production methods. You know, it's pretty much all about getting every detail just right.

One common method for creating profiles is extrusion. This process involves pushing a material, like aluminum or plastic, through a die with a specific cross-sectional shape. The material emerges as a continuous length of the desired profile. This technique allows for the creation of complex shapes with consistent dimensions, which is that it's very efficient for mass production. It’s a bit like squeezing toothpaste out of a tube, but with much more control and for industrial purposes, you might say.

Beyond extrusion, other methods such as roll forming, bending, and even additive manufacturing (3D printing) are used to produce profiles. Each technique offers different advantages in terms of material compatibility, shape complexity, and production volume. For instance, roll forming is excellent for producing long, consistent profiles from sheet metal, while 3D printing offers unparalleled freedom in creating intricate, custom geometries for prototypes or small batches. So, there's a whole range of ways to get the job done, and they all have their place, basically.

The ability to provide tailored solutions is a key differentiator for companies in this sector. Many projects require profiles that are not standard, but rather uniquely designed to fit a particular product or system. This could involve specific dimensions, unique internal channels, mounting features, or even a combination of different materials. A manufacturer that can work closely with clients to understand their exact needs and then engineer a custom profile solution adds immense value. It’s not just about selling a product; it’s about solving a problem, which is that it builds strong relationships. They really listen to what you need, you know.

This level of customization often extends to post-production processes as well. Profiles might need to be cut to precise lengths, drilled, punched, or given a specific surface finish, like anodizing or powder coating, for durability or aesthetic reasons. These secondary operations are just as important as the initial shaping process in ensuring the profile meets all functional and visual requirements. So, it's a pretty comprehensive service, from start to finish, you could say. It's almost like a bespoke suit, but for industrial components, you know.

Innovation and Future Directions in Profile Production

The world of industrial profiles is far from static; it's constantly evolving with new materials, manufacturing techniques, and demands from various industries. Companies like isoprofil gmbh & co kg are, in a way, always looking ahead, trying to anticipate what their clients will need next. This drive for innovation is what keeps the industry vibrant and responsive to global challenges. It’s a bit like a continuous race to find better ways of doing things, you know.

One significant trend is the increasing demand for lighter, stronger, and more sustainable materials. As industries strive for greater energy efficiency and reduced environmental impact, there's a growing push towards profiles made from advanced composites, recycled materials, or alloys with improved performance characteristics. This means that research and development into new material formulations and processing methods are crucial. So, you might find them experimenting with all sorts of new ingredients, basically, to make better products.

Automation and digitalization are also transforming profile manufacturing. Advanced robotics, artificial intelligence, and sophisticated software are being integrated into production lines to enhance precision, increase efficiency, and reduce waste. This allows for faster turnaround times, more complex designs, and even predictive maintenance of machinery, ensuring smoother operations. It’s that whole "Industry 4.0" thing, you know, where everything is connected and smart. This really helps to keep things moving along quickly and accurately.

Furthermore, the concept of "smart profiles" is beginning to emerge. Imagine profiles that incorporate sensors to monitor structural integrity, temperature, or even environmental conditions. These intelligent components could provide real-time data, enabling proactive maintenance or adaptive performance in various applications. While still somewhat nascent, this area holds immense potential for the future of industrial components. It’s pretty exciting to think about, really, how much more these simple shapes could do. It’s almost like they could start talking to us, in a way.

The global supply chain challenges we've seen in recent years have also put a spotlight on the importance of resilient and localized manufacturing. Companies are increasingly looking for reliable partners who can ensure consistent supply and quick adaptation to changing market conditions. This means that manufacturers of profiles are focusing not just on production quality, but also on robust logistics and customer service networks. So, it's about more than just making a good product; it's about getting it where it needs to go, reliably, which is that a lot of planning goes into it. This shift, you know, is definitely shaping how businesses operate.

Choosing the Right Partner for Your Profile Needs

When it comes to sourcing industrial profiles, picking the right manufacturing partner is absolutely critical. It’s not just about getting a component; it’s about securing a reliable supply of high-quality, precisely engineered parts that will integrate seamlessly into your own products or projects. A company like isoprofil gmbh & co kg, given its implied specialization, would likely emphasize several key aspects that clients should look for. You know, it's pretty much a big decision that impacts everything down the line.

First off, expertise and experience matter a lot. A manufacturer with a long track record and deep knowledge of materials, production processes, and various industry applications can offer invaluable insights and guidance. They can help you optimize your designs, suggest alternative materials, or troubleshoot potential issues before they even arise. This kind of collaborative approach can save a lot of time and resources in the long run. It’s a bit like having a seasoned guide for a complex journey, you might say, and that really makes a difference.

Quality assurance is another non-negotiable factor. Look for partners who have stringent quality control systems in place, from material sourcing to the final inspection of the finished product. Certifications, like ISO standards, can provide a good indication of their commitment to consistent quality. Remember, the reliability of your end product often hinges on the quality of its individual components. So, it's really about trust, and making sure that every piece is up to snuff, which is that it gives you peace of mind.

The ability to provide custom solutions is also a huge advantage. As discussed, many projects require unique profiles. A flexible manufacturer who can adapt to specific design requirements, handle complex geometries, and offer a range of finishing options will be a far more valuable partner than one who only offers standard products. This adaptability allows for innovation and differentiation in your own offerings. It’s almost like having a tailor who can make exactly what you need, rather than just buying off the rack, you know.

Finally, consider the logistical capabilities and customer support. Can they deliver on time? Do they have a responsive communication system? Good customer service and efficient logistics can make a significant difference, especially for ongoing projects or just-in-time manufacturing models. A strong partnership is built on reliability and clear communication. So, it's pretty much about the whole package, from the product itself to how it gets to you and the support you receive. You can learn more about industrial solutions on our site, and link to this page here.

In today's fast-paced industrial landscape, companies like isoprofil gmbh & co kg are more than just suppliers; they are strategic partners. Their specialized knowledge and capabilities contribute directly to the